Reciprocating compressors are typically used where high compression ratios ratio of discharge to suction pressures are required per stage without high flow rates and the process fluid is relatively dry.

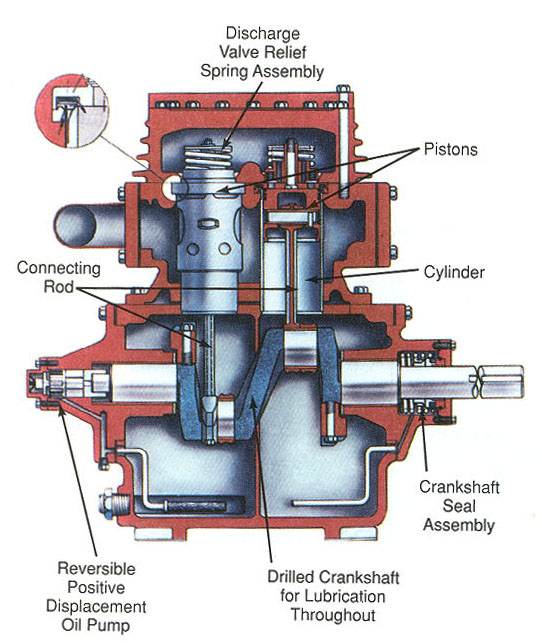

Reciprocating compressor lubrication system.

High flow low compression ratio applications are best served by axial flow compressors.

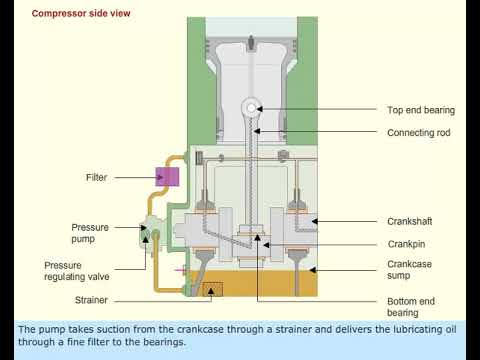

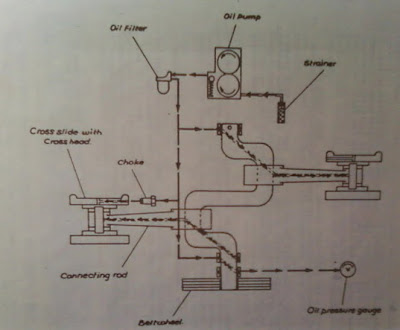

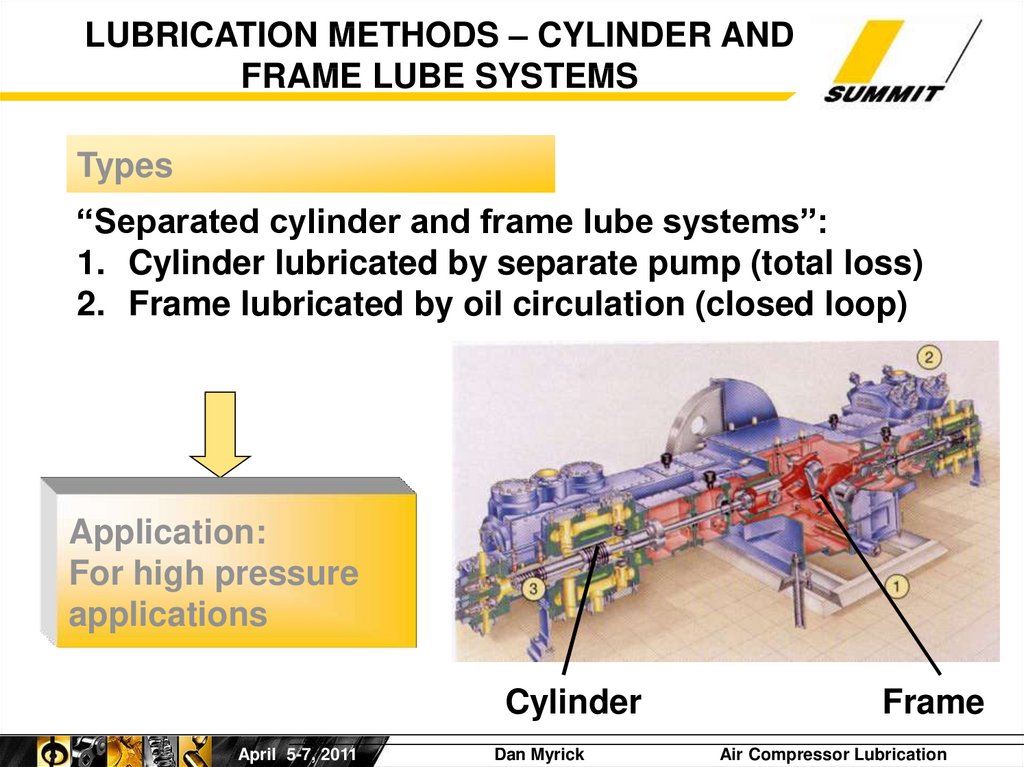

The frame lubrication system circulates oil to the frame bearings connecting rod bearings crosshead shoes and can also supply oil to the packing and cylinder lubrication system.

The major factors involved in the selection of compressor lubricants include.

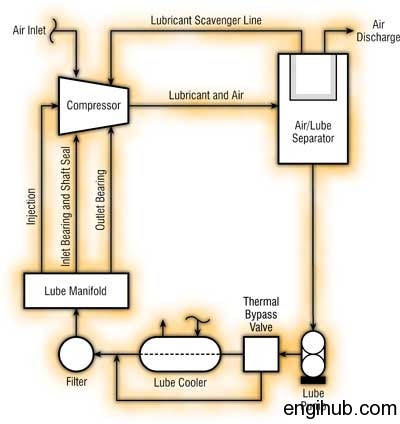

Reciprocating compressors cylinder packing lubrication system the flow required to lubricate the packing and cylinders is quite small and the pressure necessary to inject the lubricant at these locations is quite high.

Splash lubrication systems are the least expensive and are used in small air compressors.

Reciprocating compressors rely upon two lubrication systems that deliver oil to critical components in the drivetrain cylinders and packings.

Wet gas compressors tend to be centrifugal types.

The first is a recirculating system which protects bearings bushings thrust plates and crossheads in the drivetrain.

Therefore small plunger pump force feed lubricators systerns are used.

Compressor crankcase lubrication is relatively simple.

In addition reciprocating compressors are used for high pressure gas reinjection into downhole reservoirs to enhance crude oil recovery.

Type size and speed of compressor.